#automatic labeling machine technology

Explore tagged Tumblr posts

Text

Labelling Machines Market Global Market Size 2025–2035

Market Overview

The Labelling Machines Market accounted for USD 2.96 Billion in 2024 and is projected to reach USD 5.22 Billion by 2035, growing at a CAGR of around 5.3% between 2025 and 2035. These machines are widely adopted across industries like food & beverages, pharmaceuticals, cosmetics, and chemicals to automate labeling processes with efficiency and regulatory precision.

Growing consumer demand for packaged goods and automation in manufacturing are major contributors to the market growth. Furthermore, advancements in AI and IoT technologies are making labeling systems smarter and more efficient. The push for sustainable and modular packaging solutions also propels demand for innovative labeling equipment. Request Sample-https://www.metatechinsights.com/request-sample/1825

Segmental Analysis

By Product Type:

Front and Back Labelling Machines

Wrap Around Labelling Machines

Top and Bottom Labelling Machines

Side Labelling Machines

Tamper-Evident Labelling Machines

Print and Apply Labelling Machines

Full Report-https://www.metatechinsights.com/industry-insights/labelling-machines-market-1825

Wrap-around labelling machines hold the largest share due to their versatility in bottle labeling, widely used in food, beverage, and pharmaceutical sectors.

By Technology:

Pressure-Sensitive (Self-Adhesive) Labelling

Sleeve Labelling

Glue-Based Labelling

Roll-Fed Labelling

Heat Transfer Labelling

Digital Labelling Technology

Pressure-sensitive labeling dominates due to its cost-efficiency, surface compatibility, and widespread use across multiple industries.

By Application:

Food and Beverages

Pharmaceutical and Healthcare

Cosmetics and Personal Care

Chemical and Industrial

Electronics

Logistics and Transportation

Others

Buy Now-https://www.metatechinsights.com/checkout/1825

By Material Compatibility:

Plastic

Glass

Metal

Paper

Fabric

By Distribution Channel:

Direct Sales

Distributors and Dealers

E-commerce

Regional Overview

North America is experiencing significant growth due to technological advancements like machine vision, AI, and robotics. The U.S. leads in automated labeling systems, supported by environmental initiatives and increasing investments in smart factories.

Asia Pacific dominates in volume, driven by a booming middle class and expanding demand for packaged goods. Countries like India benefit from government initiatives like ‘Make in India’, pushing for local production and tech upgrades in labeling machinery.

Europe follows with high adoption rates in the food and beverage and cosmetics industries, fueled by stringent labeling regulations and sustainability mandates.

Competitive Landscape: Leading players include Krones AG, ProMach, and Sacmi Imola S.C. Krones offers modular machines with digital enhancements, while ProMach focuses on eco-friendly systems. Accutek Packaging Equipment and Fuji Seal International are integrating IoT in their labeling solutions to improve productivity and traceability.

Recent Developments:

August 2024: FOX IV Technologies launched the 6312 Label Printer-Applicator designed for SMEs, eliminating the need for external PCs.

January 2024: Domino introduced the MX-Series print-and-apply machines to improve traceability and pallet labeling under GS1 compliance.

#Labelling Machines Market#Automatic Labelling Solutions#Packaging Equipment#Food Labeling Machines#Pharmaceutical Labeling Systems#Self-Adhesive Labels#Print and Apply Technology#E-commerce Packaging#Global Labelling Industry Trends#Sustainable Labelling Equipment

0 notes

Text

Automatic Labeling Machine Market Drivers: Key Forces Fueling Global Industry Growth

The automatic labeling machine market is gaining momentum globally, driven by rapid industrial automation and the need for accurate, efficient, and high-speed labeling solutions. These machines, essential in industries such as food and beverage, pharmaceuticals, cosmetics, and logistics, are evolving in design and function to meet growing demands. With the global market expected to reach over USD 3.4 billion by 2030, understanding the key drivers behind this growth is crucial for businesses, investors, and industry professionals.

1. Rising Demand for Packaging Automation

One of the most influential drivers of the automatic labeling machine market is the increasing demand for automation in packaging processes. As manufacturers aim to enhance productivity and minimize human error, automated labeling systems offer an ideal solution. These machines streamline the labeling process, reduce labor costs, and improve overall operational efficiency. In industries with high-volume production, such as food and beverages or pharmaceuticals, automation has become a necessity rather than an option.

2. Expanding E-Commerce Sector

The explosive growth of e-commerce globally has significantly contributed to the demand for efficient labeling systems. Accurate product labeling ensures smooth logistics, helps in inventory management, and improves the customer experience. Automatic labeling machines facilitate the handling of large volumes of products by applying barcodes, shipping labels, and QR codes with high precision. As e-commerce continues to expand, especially in emerging markets, so does the need for reliable labeling solutions.

3. Stringent Labeling Regulations

Governments and regulatory bodies worldwide are enforcing stricter guidelines on product labeling, particularly in sensitive sectors like healthcare, pharmaceuticals, and food. These regulations aim to ensure consumer safety, product authenticity, and traceability. Automatic labeling machines help businesses comply with these requirements by producing consistent and tamper-proof labels. Their ability to integrate with traceability systems, such as serialization and anti-counterfeiting features, adds further value in regulated environments.

4. Technological Advancements and Smart Labeling

The adoption of smart technologies such as RFID (Radio Frequency Identification), IoT (Internet of Things), and AI (Artificial Intelligence) has transformed the labeling industry. Modern automatic labeling machines are now equipped with intelligent systems that offer real-time tracking, error detection, and remote operation capabilities. These advancements not only improve efficiency but also enable better decision-making and inventory control. Companies investing in smart labeling are gaining a competitive edge in terms of quality assurance and data analytics.

5. Growth in the Food and Beverage Industry

The food and beverage industry holds a significant share of the automatic labeling machine market. This sector demands fast, accurate, and hygienic labeling solutions to ensure compliance with food safety standards and consumer expectations. With the increasing consumption of packaged foods and beverages globally, manufacturers are upgrading to automatic labeling systems that support diverse packaging formats and label types. Product traceability, nutritional labeling, and expiration date accuracy are critical aspects driving this trend.

6. Pharmaceutical and Healthcare Applications

Pharmaceutical companies are among the early adopters of automatic labeling machines due to their need for precision and compliance. Labels on medicine bottles, vials, and cartons must contain critical information such as dosage, manufacturing date, batch number, and warnings. Given the strict regulations in the pharmaceutical industry, labeling errors can have serious consequences. Automatic machines ensure consistent and error-free application, making them indispensable in healthcare manufacturing units.

7. Sustainability and Eco-Friendly Labeling

Sustainability trends are shaping the automatic labeling machine market as companies aim to reduce their environmental impact. Eco-friendly label materials, recyclable packaging, and reduced waste in the labeling process are becoming standard expectations. Automatic labeling machines that support water-based adhesives, linerless labels, and energy-efficient operations are gaining popularity among environmentally conscious manufacturers. This shift is particularly strong in Europe and North America, where green initiatives are heavily promoted.

8. Regional Market Expansion

The Asia-Pacific region is currently leading the automatic labeling machine market, accounting for over 38% of the global share. Rapid industrialization, growing consumer markets, and government support for automation in countries like China, India, and Thailand are fueling this growth. Meanwhile, North America and Europe are experiencing steady demand due to their mature industrial infrastructure and focus on technological upgrades. Latin America and the Middle East are emerging markets with increasing investments in automation technologies.

Conclusion

The automatic labeling machine market is on a robust growth path, driven by a combination of industry needs, technological innovations, and regulatory frameworks. As businesses prioritize efficiency, accuracy, and compliance, the demand for automated labeling solutions will continue to rise. Understanding these key drivers allows companies to strategically invest in labeling technologies that not only enhance productivity but also support long-term growth and sustainability goals.

#Automatic Labeling Machine Market#Packaging Automation#Labeling Technology#Smart Labeling Solutions#Industrial Automation

0 notes

Note

I'm a trans guy who's currently working in a trade school, specifically taking a digital printing technology program (so like silkscreening, pre-press, embroidery, lazer cutting, label making, etc.) and when I see CNC I just automatically think about CNC (Computer numerical control) machine. It's basically a giant machine to cut stuff like wood, aluminum, film, foam, stuff like that.

Fun fact: I actually took a course in CNC programming in high school.

Funny anecdote but imagine being in University in a degree where you have to take psych classes at the height of "CBT" memes. Our professor would always talk about "Cognitive Behavioral Therapy" and my and my friends would have to not laugh because all we could think about was cock and ball torture.

18 notes

·

View notes

Text

Domino Presents New Monochrome Inkjet Printer at Labelexpo Southeast Asia 2025

Domino Printing Sciences (Domino) is pleased to announce the APAC launch of its new monochrome inkjet printer, the K300, at Labelexpo Southeast Asia. Building on the success of Domino’s K600i print bar, the K300 has been developed as a compact, flexible solution for converters looking to add variable data printing capabilities to analogue printing lines.

The K300 monochrome inkjet printer will be on display at the Nilpeter stand, booth F32, at Labelexpo Southeast Asia in Bangkok, Thailand from 8th–10th May 2025. The printer will form part of a Nilpeter FA-Line 17” hybrid label printing solution, providing consistent inline overprint of serialised 2D codes. A machine vision inspection system by Domino Company Lake Image Systems will validate each code to ensure reliable scanning by retailers and consumers whilst confirming unique code serialisation.

“The industry move to 2D codes at the point of sale has led to an increase in demand for variable data printing, with many brands looking to incorporate complex 2D codes, such as QR codes powered by GS1, into their packaging and label designs,” explains Alex Mountis, Senior Product Manager at Domino. “Packaging and label converters need a versatile, reliable, and compact digital printing solution to respond to these evolving market demands. We have developed the K300 with these variable data and 2D code printing opportunities in mind.”

The K300 monochrome inkjet printer can be incorporated into analogue printing lines to customise printed labels with variable data, such as best before dates, batch codes, serialised numbers, and 2D codes. The compact size of the 600dpi high-resolution printhead – 2.1″ / 54mm – offers enhanced flexibility with regards to positioning on the line, including the opportunity to combine two print stations across the web width to enable printing of two independent codes.

Operating at high speeds up to 250m / 820′ per minute, the K300 monochrome inkjet printer has been designed to match flexographic printing speeds. This means there is no need to slow down the line when adding variable data. Domino’s industry-leading ink delivery technology, including automatic ink recirculation and degassing, helps to ensure consistent performance and excellent reliability, while reducing downtime due to maintenance. The printer has been designed to be easy to use, with intuitive setup and operation via Domino’s smart user interface.

“The K300 will open up new opportunities for converters. They can support their brand customers with variable data 2D codes, enabling supply chain traceability, anti-counterfeiting, and consumer engagement campaigns,” adds Mountis. “The versatile printer can also print variable data onto labels, cartons, and flatpack packaging as part of an inline or near-line late-stage customisation process in a manufacturing facility, lowering inventory costs and reducing waste.”

Code verification is an integral part of any effective variable data printing process. A downstream machine vision inspection system, such as the Lake Image Systems’ model showcased alongside the K300, enables converters and brands who add 2D codes and serialisation to labels and packaging to validate each printed code.

Mark Herrtage, Asia Business Development Director, Domino, concludes: “We are committed to helping our customers stay ahead in a competitive market, and are continuously working to develop new products that will help them achieve their business objectives. Collaborating with Lake Image Systems enables us to deliver innovative, complete variable data printing and code verification solutions to meet converters’ needs. We are delighted to be able to showcase an example of this collaboration, featuring the .”

To find more information about the K300 monochrome printer please visit: https://dmnoprnt.com/38tcze3r

#inkjet printer#variable data printing#biopharma packaging#glass pharmaceutical packaging#pharmaceutical packaging and labelling#Labelexpo Southeast Asi

2 notes

·

View notes

Text

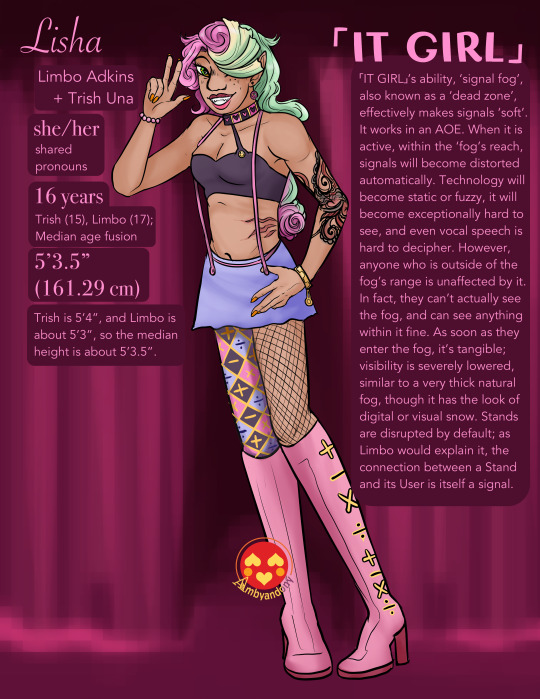

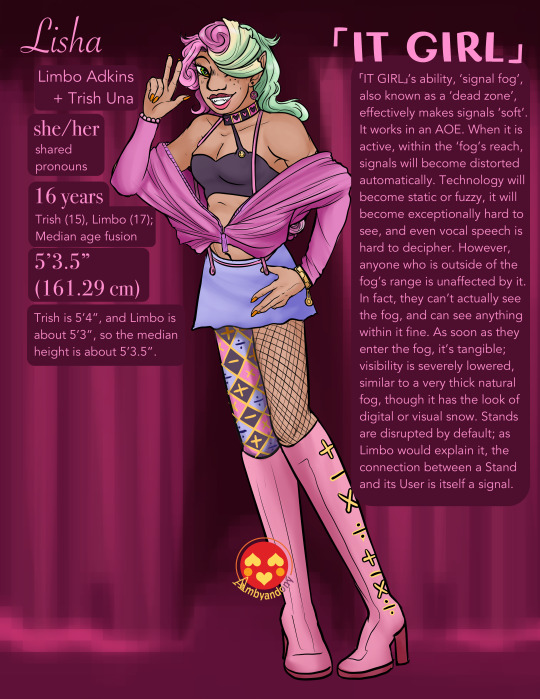

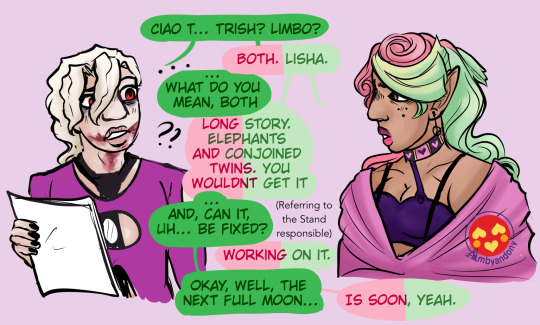

Fusion (JJBA) - “Lisha Adkuna”

Limbo Adkins + Trish Una

presenting the fusion of my oc limbo with Trish for absolutely no reason I just was thinking about her so fuckinn much . specifically a monster au variant for reasons i dont really know.

"Lisha" Adkuna (either Lih-sha or Lee-sha add-kew-nah), fusion of Limbo Adkins and Trish Una, User of fusion Stand 「IT GIRL」.

A 「My Space」*-classic median fusion, meaning that most of her basic traits fall between what they are for Trish and Limbo; thus, she's 16 years old, about 5'3.5" or 161.29 cm tall, and - as is common for fusions where components share the same pronouns, she/her in this case - is identifiable by she/her rather than they/them.

She has a soft, light, somewhat high-pitched voice, fairly reminiscent of Rosemary Fairweather (which incidentally was another possibility for the Stand name), a la 'Washing Machine', which is incidentally also her musical style, considering Limbo is a musician and post-PHF Trish is a pop star. makes the best collab ever with myself

Fusions with Limbo tend to automatically take her cloud tattoo and present it differently in a way that relates to the fusion in some way. Lisha's tat is... particularly drastic in difference and... interesting, to say the least.

Side note. That's a bracelet. Her hand is fine.

(* see bottom of post)

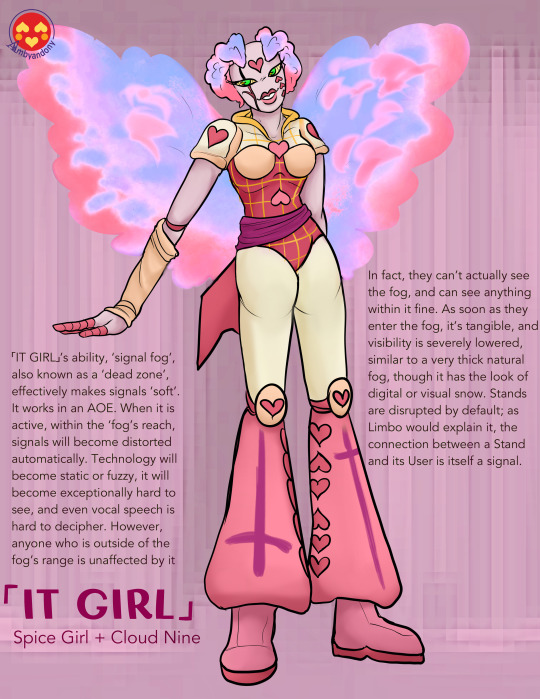

The fusion between Trish's 「Spice Girl」 and Limbo's 「Cloud Nine」 is

「IT GIRL」.

「IT GIRL」’s ability, ‘signal fog’, also known as a ‘dead zone’, effectively makes signals ‘soft’.

It works in an AOE. When it is active, within the ‘fog’s reach, signals will become distorted automatically. Technology will become static or fuzzy, it becomes exceptionally hard to see, and even vocal speech is hard to decipher.

However, anyone who is outside of the fog’s range is unaffected by it. In fact, they can’t actually see the fog and can see anything within it fine. As soon as they enter the fog, it’s tangible; visibility is severely lowered, similar to a very thick natural fog, though it has the look of digital or visual snow.

Stands are disrupted (though not disabled) by default; as Limbo would explain it, the connection between a Stand and its User is, itself, a signal.

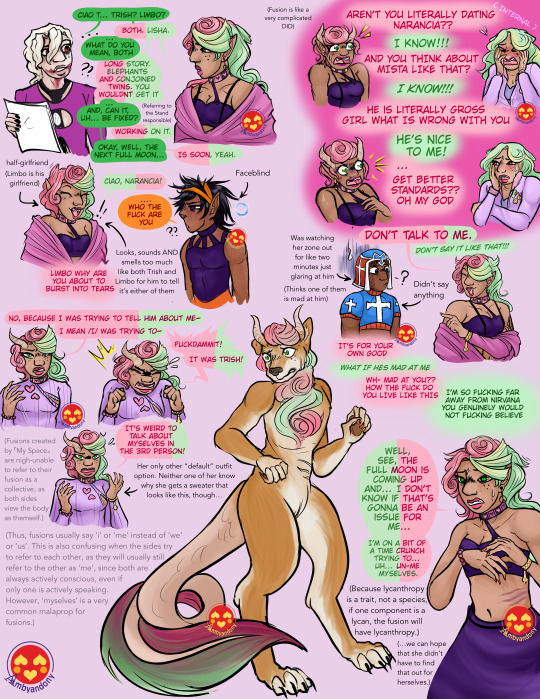

I made a sketch sheet too but it's ambiguously-anachronistic aka i can't tell you at what point in the timeline this would be occurring since

1. fugo is clearly post phf,

2. narancia and limbo have not gotten together with mista yet,

3. narancia.

so basically just dont worry about it

text is kinda small though so here's close-ups

Fugo: Ciao, Tr.. Trish? Limbo?

Lisha: Both. Lisha.

Fugo: ... What do you mean, 'both'

Lisha: Long story. Elephants and conjoined twins. You wouldn't get it

Fugo: ... And can it, uh... be fixed?

Lisha: Working on it.

Fugo: Okay, well, the next full moon-

Lisha: Is soon, yeah.

(Lisha, labelled in a side note as "half-girlfriend (Limbo is his girlfriend)

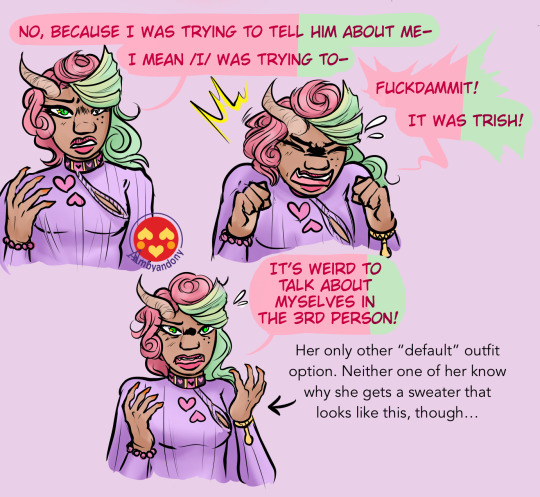

Lisha, Limbo voice, with delight: Ciao, Narancia!

Narancia, labelled "faceblind": ..... who the fuck are you

(Lisha is further labelled, "looks sounds and smells too much like both Trish and Limbo for him to tell it's either of them")

Internal Trish voice: Limbo why are you about to burst into tears

Lisha, Trish voice: No, because I was trying to tell him about me -

Lisha-Trish, continued: I mean I was trying to -

Lisha-Trish, continued, angrily: FUCKDAMMIT! It was Trish!

Lisha-Trish, continued, exasperated: It's weird to talk about myselves in the third person!

( a side note to her right points to her purple keyhole sweater and reads "Her only other "default" outfit option. Neither one of her know why she gets a sweater that looks like this, though... )

(Internally)

Trish: AREN'T YOU LITERALLY DATING NARANCIA!?

Limbo: I know!!!

Trish: AND YOU THINK ABOUT MISTA LIKE THAT?!

Limbo: I KNOW!!!

Trish: He is literally gross girl what is wrong with you

Limbo: He's nice to me!

Trish: ...

Trish: GET BETTER STANDARDS??? OH MY GOD

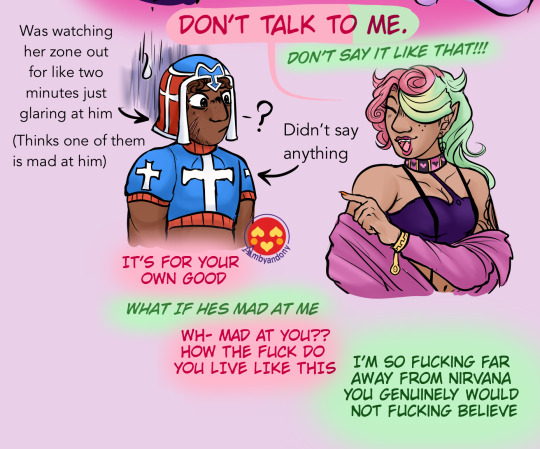

(Externally)

Lisha, Trish voice: (points threateningly at Mista) Don't talk to me.

Internal Limbo voice: DON'T SAY IT LIKE THAT!!!

Mista: (Didn't say anything) (Was watching her zone out for like two minutes just glaring at him (thinks one of them is mad at him))

(Internally)

Trish: It's for your own good.

Limbo: What if he's mad at me!!

Trish: Wh-mad at you!?? How the fuck do you live like this?!?

Limbo: I'm so fucking far away from nirvana you genuinely would not fucking believe

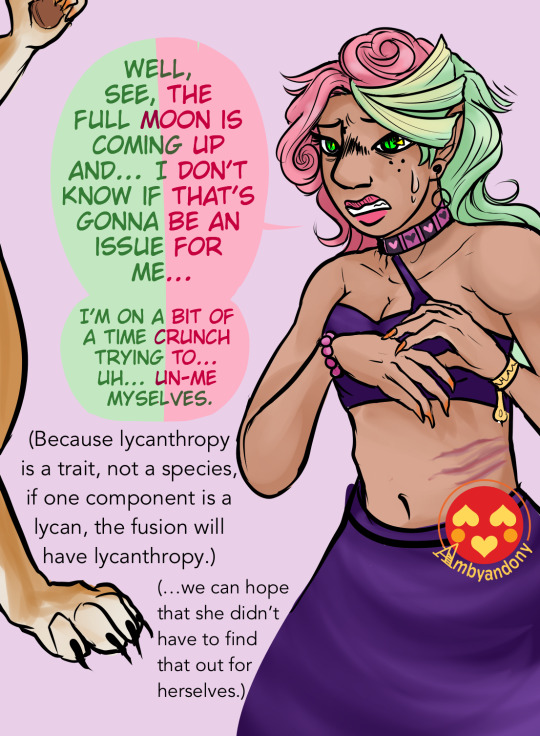

Lisha: Well, see, the Full Moon is coming up soon and... I don't know if that's gonna be an issue for me... I'm on a bit of a time crunch trying to... uh... un-me myselves.

* 「My Space」 is a Stand belonging to a pair of conjoined twins (Eve and Belynda, or "Evelynn"). It takes a form resembling a conjoined pair of elephants, and its ability is simply to fuse two individuals into a single entity, both fusing their physical form and their Stands. Due to the way it does this, fusions function as a collective or co-consciousness, akin to a sort of very complicated Dissociative Identity Disorder; both components are generally actively conscious at all times, though they are able to speak either collectively or individually.

Considering this shared consciousness, fusions created by 「My Space」 are practically unable to refer to their fusion as a collective, as both sides view the body as themself. Thus, fusions usually say ‘i’ or ‘me’ instead of ‘we’ or ‘us’. This is also confusing when the sides try to refer to each other, as they will usually still refer to the other as ‘me’, since both are always actively conscious, even if only one is actively speaking. However, ‘myselves’ is a very common malaprop for fusions.

Evelynn refuse to undo the fusions unless their victim tracks them down and is able to convince them, usually by amusing or impressing them with some kind of talent or skill. They consider their Stand's ability a performance and insist it's only fair that they're entertained in return (really most of the separating process is just trying to track the twins down).

#probably not canon to monster au#golden wind#vento aureo#my space fusion arcs#jjba#jjba fanart#monster au#jojo fanart#jojos bizarre adventure#jojo's bizarre adventure#jjba monster au#jojo au#jjba au#so this is what homeworld thi-#monster au meme#Pannacotta Fugo#Fugo Pannacotta#Trish Una#Guido Mista#Narancia#Narancia Ghirga#Limbo Adkins#jjba oc#jojo oc#fanstands#amby draws#my art#monster au profile#limbo fusions#lisha adkuna

18 notes

·

View notes

Text

Mechanosis

Chapter 2: 불 (fire)

불

fire

Music drifted through Gyeongseong Station at four in the morning.

Usually, San was awoken by the chiming clock, and would ready himself for work then sit and watch the sunrise while Hongjoong slept in, tired from a late night before.

Today, they were both roused earlier than expected by the sweet melody of a flute in the station below.

Separating himself from a grumbling Hongjoong, San peeked down towards the tracks to find the mysterious flute player.

A woman stood there with a basket in front of her to collect coins from passing strangers, and from the looks of it had amassed a small amount already in the business of the morning commute to various factories across Hanseong.

People were resilient in the face of new problems, and San watched her play with a soft smile on his face, even though he had nothing to share with her.

The click of boots on the tile floor drew his attention away, and at the end of the corridor he saw the station inspector, making a beeline for the musician.

Disappointed, San watched him approach her and confiscate both her instrument and her money basket, claiming in a loud voice that such public performances were illegal as ordered by the Ministry of Technological Advancement.

She was sent away, dejected, with a warning and San retreated to his hiding place, where Hongjoong had dressed for work and was waiting for him.

They didn’t speak on the walk to Namsan, keeping their heads down and moving at as quick a pace as they could with Hongjoong only having half his vision and trying not to be run over by any of the steam-powered palanquins, wooden carts, and sundry vehicles taking to the roads in the morning.

Namsan factory was strangely abuzz with chatter when they arrived, and the pair nudged their way to the front of the crowd to attempt to find out what they were all staring at.

As he glanced up at the massive overhead sign meant to display a comparison of their daily quota with the currently produced number of machine parts to track their progress, San began to understand why.

The number was over twice as high as usual. It was outrageous.

Never in a single day could he produce so much, let alone Hongjoong who struggled to use his peripheral vision.

As his gaze swept the room, San noticed a few additions to the machines they typically worked with. Finally, a supervisor came forward to demonstrate the usage of a number of brand new saw-type machines added to the assembly line since yesterday.

“You may have noticed your daily quota has increased,” he stated redundantly. No one dared answer him. “This is due to our great Innovator’s newest design— an automatic blade that drops by itself every thirty seconds. You must work faster to keep up, so as a result our production will increase exponentially.”

“There are no guards or tethers,” Hongjoong muttered to San as he inspected it from afar. “Nothing to prevent it from chopping your fingers clean off if you aren’t quick enough.”

San forced down a gulp at the prospect. He knew he’d have to handle the metal monster soon enough, as the blade did not retract automatically, but would need to be pushed back up into its natural position after each usage.

He spent the work day getting acquainted with it as quickly as possible to avoid being punished by the supervisors. Their demands were especially high today, and a salary cut or even being laid off was too dangerous for someone in his position.

“Hurry up, you idiot!” A man suddenly yelled from farther down the line.

It took a moment, but San realised it was the worker on the left side of Hongjoong, yelling at him for being too slow again. Thankfully, they’d been placed a little behind the automatic saw contraption and were busy labelling metal sheets, but a few had congregated in Hongjoong’s space and clogged up the line as he struggled to see the new materials San was handing over from his right unless he turned his head constantly.

Attempting to placate the man, Hongjoong gave a small bow of apology and explained, “I’m sorry, I didn’t know more had come, I couldn’t see—”

The worker didn’t care to hear his excuses.

“You can see fine!” He argued in an irritated tone of voice. “Why do you wear that bandage still anyway? It’s been years!”

Without any sort of permission or cause, the man pushed himself into Hongjoong’s space and ripped the bandage from his head aggressively to prove his point.

Anger spiking inside him, San put himself between the two, first checking that Hongjoong was alright where he curled in on himself and pressed his hands to the burn scar on his face in rigid embarrassment.

When he saw the moisture in his hyung’s eyes, both tear ducts still intact, San wasn’t afraid to get in the worker’s face to fight back.

“How dare you? You know nothing about him, you should back off—”

“What’s going on there?”

A supervisor’s sharp scolding interrupted and all three participants bowed their heads in apology, none answering.

“Who is responsible for this?” The man asked, annoyed. Before either could get a word in edgewise, the other worker pointed at Hongjoong, who was now on the floor feeling around for his bandage, wherever it had fallen.

“Come here,” the supervisor ordered him, giving only seconds to act before he hauled Hongjoong up, taking his face in a tight grip and turning it back and forth after wrenching his protective hands away.

San clenched a fist at his side but forced himself not to act. They could still make it out of this with a warning.

Still, he saw the way Hongjoong’s face burned with crimson shame. It didn’t matter whether his eye was “healed” or not, he clearly couldn’t see out of it and the wounded appearance being viewed by others was something upsetting to Hongjoong. Even San had only seen his eye a number of times, mostly accidental.

“You’re fine,” the supervisor announced curtly before dishing out punishment. “Leave this factory. You will be paid nothing for the day, return tomorrow and do not slack off again. If you cause another incident, you’ll be dismissed on the spot. Now you’ve been forewarned.”

Stiffly, Hongjoong bowed his thanks and removed his work apron, head down so his hair would cover his face from view. The room was so quiet, San could swear he could hear his hyung’s heartbeat.

As soon as the supervisor’s back was turned, San snatched up the bandage and reapplied it on Hongjoong’s face, walking him to the entrance where they could share a few brief words.

“Hyung, I’m so sorry, I wish I could do something,” he told him sincerely.

Even with his eye covered, Hongjoong still wouldn’t look at him.

“Everyone was watching, the whole factory,” he whispered through tightness in his throat. “It was humiliating.”

“Hyung—”

“And now you’ll have to work alone!” Hongjoong let out a dark chuckle. “I’m sorry I’m so useless, I promise I’ll use the time to buy you food or something.”

“You’re not useless,” San insisted, maintaining eye contact for as long as he could until Hongjoong shook his head and glanced away.

“I’ll pick you up after work?” The older changed the subject, clearing his throat to remove any building emotion. San sighed in response, as always.

“Yes, I’ll see you then.”

“Be safe,” Hongjoong warned. “Take breaks if they let you.”

And that was it. San didn’t see him for the rest of the work day.

Despite knowing he wouldn’t be paid double, he worked twice as hard to cover Hongjoong’s absence anyway, wary of the worker next to him causing another incident.

At the end of the day, they were all trying to collect their pay and make it home. This man was no different.

Famished and hacking up what felt like all the moisture in his lungs, San didn’t even realise when closing time came without a single break for rest or water and he had labelled hundreds of products until the line stopped running and the workers began to clock out.

Blinking his bleary eyes, he glanced at the exit to see Hongjoong waiting for him. San’s feet moved towards his hyung of their own accord and his body practically melted into him.

“I’ve got you,” Hongjoong whispered so only he could hear, and San put his arms around the older man’s neck and climbed onto his back for the walk home. His legs could hardly carry him anymore.

“‘M hungry,” he whined, knowing he sounded like that fourteen year old child he’d been when they met those years ago. “Did you get food?”

“It’s waiting back at the hideout, Sannie,” Hongjoong consoled him with a pat to the knee as he navigated the crowded evening streets in the direction of the station. Home. “Just hang in there a little longer.”

Even when he had been laid down on his sleeping mat and food had been spooned into his mouth, the constant harsh cough wouldn’t let him sleep.

Whimpering from the pain in his throat, San curled up and let Hongjoong pet him, pushing sweaty hair off his forehead and placing a wet cloth on it.

“Does that feel better, Sannie?”

Sannie.

Hongjoong only used the nickname when San wasn’t doing well. Tonight was one of those nights. Perhaps worse than it had ever been before.

“Mhm,” he hummed in agreement, trying to coax a smile from his anxious hyung, but it wasn’t enough.

He was still in pain and his body felt like it was on fire.

For what seemed like hours, he squirmed in bed, throwing the blankets on when a chill overtook him and then off again when the fever spiked and the blankets were suffocating.

“So hot,” he cried, knowing he sounded pathetic and not caring about it. Everything hurt so bad, and there was no end in sight.

“I know you are, Sannie,” Hongjoong murmured, chewing on his lip nervously. “I’m going to go fetch some medicine, alright? Is it okay if I go do that?”

“What?” San whispered hoarsely, trying to rise from the bed in a panic. “N-No, don’t leave me alone, hyung, please.”

“I know and I’m sorry,” Hongjoong told him softly, gently removing his hand from where San was clutching him like a lifeline. “But I need to get something to bring your fever down and treat that horrible cough of yours. Don’t you want to sleep peacefully tonight?”

Tears filled San’s eyes. He did want to.

Peaceful sleep, uninterrupted by his torturous cough, sounded like a dream too good to be true. But he was afraid of closing his eyes and drifting away all alone. What if he couldn’t open them again? What if he died in his sleep right there and Hongjoong didn’t make it back in time?

Was he being abandoned right now?

“No, no, please,” San sobbed, outright crying now despite the spikes of pain in his throat every time he made noise. “You can’t leave me, we can’t afford medicine, I don’t want to die—”

Hongjoong shushed him reassuringly, hugging him close before laying him down again, leaving water and blankets in close reach. “You won’t die, San. You’re going to be fine, alright? I promise you.”

Lower lip trembling with the urge to sob aloud again, San nodded in acceptance of his promise.

If Hongjoong was promising, he meant it.

___

Yeosang tapped his fingernails against the counter idly. He was wrapping up his evening at the apothecary shop and neither Yunho nor his friend had made an appearance yet the entire day.

In fact, only a handful of people had made appearances at all and they were ministry officers, people Yeosang was wary of— and certainly not hoping to run into again.

There were days in his highly illegal career of ferrying traitors away from Joseon that had passed with much more thrill and exhilaration. Despite knowing those moments when he let his guard down were the most dangerous, Yeosang’s boredom couldn’t keep him awake, and he caught himself dozing off behind the desk three times before a customer entered and the chimes by the door alerted him.

“Hello? Could you help me?”

The raspy voice of the customer sounded, somewhat panicked, so Yeosang straightened his apron and flashed a reassuring smile. Years of pretending to be friendly for the yangban made it an easy habit to fall back on.

“Yes, what can I get for you?”

The man turned his head around and gave him a once-over, Yeosang returning the favour and taking stock of his visitor.

He looked to be about the same age, height on the shorter side, with dark, disheveled hair, and a curious bandage wrapped around his head, covering his right eye.

“Perhaps an ointment or optical treatment—” Yeosang commented, already reaching for the nearest shelf with eye cream.

“No, no, for my friend,” the customer panted, regaining his breath as he clearly must have run there. “His lungs are weak from the smoke and he’s worked himself to the point of sickness again.”

There was desperation written all over him, though he tried to rationally explain the symptoms.

“His cough is worse than usual, and he’s burning up with a terrible fever and these chills— he hasn’t been able to rest at all, he’s too uncomfortable— and I’m worried, please, tell me you have something for him.”

While Yeosang did have medicines stocked and was glad to sell them, he was painfully aware as he rifled through the supplies that he was no licensed apothecary and that his forays into chemistry didn’t typically involve experiments of a medical nature.

Most days, the shop was managed by an actual physician, one who would gladly step aside and take a day or two off when Yeosang needed access to his favourite central hub to keep an eye on someone.

“Well, there are a number of tonics here that could potentially bring down a fever,” he noted, trying to sound professional. Another chime from the door drew his gaze and immediately distracted him.

It was Yunho’s friend— the man who had reportedly been his servant before— entering the shop and idling near the skin treatments.

“Which is best?” The anxious customer asked, leaning over the front desk as if to see the vials Yeosang had in front of him. “I don’t care how expensive. I’ll give you everything I have, the clothes off my back if I have to.”

“Here,” Yeosang picked one at random and handed it to the man, not even glancing at the label. “Take this one. Go.”

“B-But how much is it?” He stuttered in surprise, turning the small bottle to find a price tag. From the way he blanched, it must have been expensive. “Won’t you ask me to pay?”

“No,” Yeosang practically hissed, eyes darting back and forth as he tracked the mysterious stranger across the room. He needed to speak with him, privately, and the interaction with this customer had gone on for too long. “It’s on the house, just take it for free. I trust you can see yourself out?”

“Yes, of course!” The man’s face brightened with gratitude and he pocketed the vial before heading for the exit, calling over his shoulder, “Thank you so much!”

Yeosang didn’t respond, eyes still on the tall stranger while the other customer left. Regardless of the number of times he had made contact with the important targets he spent so much time spying on, it was always slightly nerve wracking to initiate dangerous discussions with someone whom he may have misjudged.

Just as he was about to approach him and begin his investigation, the man moved towards the door and stopped in front of it suddenly.

The telltale sound of the lock clicking followed a moment later.

It seemed this man also desired a conversation alone with Yeosang. From the way his back tensed, it looked like he was poised to strike, and Yeosang found his fingers subconsciously moving towards the knives hidden under the desk.

Just as his hand wrapped around the handle, the stranger turned and launched himself over the desk, pinning Yeosang to the wall with a clockwork pistol to the forehead.

The knife in Yeosang’s hand was poised against the man’s neck, having been raised just in time to lock the two in an impasse.

“Who are you?” The stranger growled in a sonorously imposing voice.

Finally able to get a look at him now that he was so close, Yeosang noticed the intense glint in his small eyes, his sharp nose and the way his full lips were pressed together as he gritted his teeth. He looked seconds off from murder, and capable of it, too.

Yeosang decided to provoke him.

“What, you aren’t going to introduce yourself first? It seems only proper, seeing as you started the conversation.”

“Song Mingi,” he barked before leaning in closer, ever so subtly insecure that his intimidation wasn’t working.

“Jeong Yunho’s friend?” Yeosang confirmed, watching Mingi’s face tighten nearly imperceptibly at the name. “I’m Kang Yeosang. I only want to talk.”

“You’re a spy, aren’t you?” Mingi snapped back quickly, tilting his head almost mockingly. “Master Jeong put you up to this, didn’t he?”

Confusion clouded Yeosang’s mind for a moment before he realised what was going on, and answered calmly, “No, I don’t work for his father.”

The presence of the gun made itself known again, pushed harder into his temple as Mingi growled, “Then who?”

“Listen,” Yeosang huffed, lowering the knife and trying to squirm away. “If you’d let go of me, maybe I’ll explai—”

“Tell me who hired you!”

Yeosang froze as Mingi’s yell shook the apothecary shop. For a moment it was just the sound of their breathing until Mingi realised he’d lost control of himself and took a small step back so Yeosang had room to lift his hands, palms out, between them.

“No one,” he explained slowly. “I work with a man they call the Mechanist. Not for him, with him.”

Mingi’s brow was furrowed in thought as he stared into space contemplatively. Clearly he hadn’t considered this as a possibility.

It gave Yeosang the space to slide out of his grip and return to his place behind the desk, hand falling on the knife again even while he faced the attacker standing behind him. Just in case.

“That’s why I needed to catch you alone in the shop,” he went on, as unthreateningly as possible. “So the spies tailing you wouldn’t be alerted.”

“Funny,” Mingi scoffed, crossing his arms. “That’s why we kept returning to the shop. Because we thought you were one of them, and thought to smoke you out.”

“Well!” Yeosang laughed awkwardly, hoping it would loosen Mingi up. “What a coincidence.”

When finally the man holstered his weapon, Yeosang allowed himself a moment of jealousy.

Seonghwa always insisted they operate on a no-technology fighting style. No clockwork, no steam engines, just good old fashioned household items. And crossbows.

“That’s a nice pistol you’ve got there,” he commented dryly. “Where’d you get it?”

Mingi responded with a deadpan, “Where do you think? My former master was an entrepreneur.” He cut straight to the point a moment later, “What is it you want with us then?”

Just as eager to drop the small talk and finish business before real customers began to wonder why the door was locked, Yeosang passed over a letter he’d written and sealed with Seonghwa’s stamp.

“To beg the help of your friend, Yunho. We believe he may be aligned with our cause and serve as a great asset to it.”

“And what would he receive in return?” Mingi snorted, taking the paper and turning it over in his hands as if to inspect its exterior.

“He’s a detective, isn’t he?” Yeosang asked rhetorically with a growing smile. “Perhaps I have some useful information for him.”

___

The day San’s fever broke, Hongjoong wasn’t home.

All week since giving him the medicine, he worked in the factory by day and tended to his friend by night.

There was no time for sleep, and rarely any time for finding food.

Still, San’s health would not improve without it, so he stole away from his bedside when he got the chance and traded his wages for groceries.

It was one such evening that San opened his misty eyes to see the crisscrossing metal beams of the station ceiling, no longer delirious but alone, and realised his life had been saved.

Nonetheless, he was in a panic when Hongjoong returned with his arms full of supplies that night, only to be tackled in a hug that he couldn’t pry himself out of.

“I thought you had left me,” San whispered when finally Hongjoong dropped his things and hugged him properly, no longer too stunned to react.

“Never,” Hongjoong insisted just as fiercely.

“Did you heal me?” San hesitantly asked over their late evening meal, much more shyly than Hongjoong was used to from him.

“The medicine healed you,” scoffed Hongjoong, shaking his head in joyous disbelief. “I just kept you comfortable as best as I could.”

“Thank you,” San replied softly, with a wide smile. His dimples were on full display, and he ate his food so vigorously, it put Hongjoong’s mind at ease that he must have done well indeed.

“You feel better?”

“Much better!” San chirped with his mouth full. “I can come with you to the factory tomorrow, so you won’t have to work alone anymore. I wouldn’t wish that on anyone.”

“But that’s what got us into this mess,” Hongjoong pointed out in warning, shifting where he sat with his legs crossed to relieve some of the soreness of constant motion. “I don’t want… I don’t want to lose you again.”

It was vulnerable, much more vulnerable than he usually was, and San knew what it took for him to say such a thing.

“You won’t,” he promised, reaching out to squeeze his hyung’s shoulder. “I’m not going anywhere.”

True to his word, the next day he departed for the factory alongside Hongjoong, and together they manned the new machines, positioning sheets of metal to be sliced in half by them.

The danger of operating such an invention was heightened by the lack of sleep, but Hongjoong did his best to keep his eyes open and trained on San when he could.

He hid it well, but he was still weak from the intense illness he had recently overcome. And he was always wearing those shirts that were too big for him.

Twice before the lunch break, he nearly got part of his sleeve chopped off, giving Hongjoong a near heart attack, but scolding him was no use. He didn’t have anything else to change into, and it was too cold to remove any clothing anyway.

At the end of the day, it finally happened.

The cuff of San’s dopo caught on the edge of the slicing area after he had reached across and then moved to pull his hand back.

He tried to wrench it free, but from his side of the machine it couldn’t be done without ripping the fabric.

“Hyung!” He cried, knowing the blade would descend any moment now. His dominant hand frustratingly gloved at the moment, Hongjoong quickly reached across with his left hand and attempted to wriggle it free, panic building in both of them as it ever so slowly gave way. It was taking too long.

Only seconds remained before the scheduled chopping, and feeling like he was moving in slow motion, Hongjoong finally freed the sleeve and pushed it back out the other side to remove San from harm’s way.

The blade dropped automatically just before he pulled his own hand clear, and a sickening crunch echoed through the factory.

Hongjoong’s heart stopped.

All around him, there was stillness. Like the entire world had frozen in place, with a great gasp going up from the other workers.

San rushed to force the blade up, and almost completely numb, Hongjoong tried to flex his fingers. He couldn’t move them. He couldn’t even feel them. There was no sense of anything below the wrist until the shock was overcome by pain.

Consuming, overwhelming pain.

“Oh, oh no…”

His throat was closing in on itself from the panic as he watched blood pour continuously out of his hand. Where his hand used to be.

It was like a fountain spurting red in pulses with every heartbeat, and he watched in morbid fascination, slowly becoming nauseated by it.

“Sannie, I can’t… my hand…” he muttered through the haze in his brain, weightlessness descending on him. It was so hot, he was choking on the fire that spread from his wrist to the rest of his body.

Hongjoong blinked and suddenly he was on the floor. His legs had given out, and there was a wetness on his face.

Tears. He was crying.

“San?”

Where was San? He was too dizzy to recognise anyone in the surrounding crowd, everyone’s face a blur.

All over again, Hongjoong felt like a child.

Scared and alone on a factory floor, and his parents were dead and no one would help him, and blood was everywhere and it was so much, so much blood—

“Hyung! Hyung, I’m here, please stay awake.”

San’s voice.

Hongjoong wrenched his eye open, unsure when it had closed, and turned his head until San came into view.

He looked scared, more scared than Hongjoong had ever seen him even when he was deathly ill, and it caused chilling dread to take root in his stomach.

“Is it bad?” He whispered, though he wasn’t sure if the words came out.

San seemed to tell from the movement of his lips and checked the stump of flesh that remained of Hongjoong’s hand, pressing his own shirt to it tightly. Immediately, it was soaked through with deep red.

“It’s… I don’t want to lie to you, hyung, it looks bad, but I’m sure you’ll be alright!” San forced a smile, but he was crying now too, and turned to yell at the gathered crowd of factory workers, continuing to add fabrics to cover the wound, from his own dopo to Hongjoong’s durumagi.

“Don’t just stand there, all of you! Someone help, please! Call the authorities or a doctor or something, someone—”

No one moved an inch.

“What’s going on over there?” A supervisor barked from behind the mass of faces. “Get back to work!”

Hongjoong tried to obey, he’d already been issued a warning once, but couldn’t bring himself to stand. His life was draining at the site of his severed hand and he knew he didn’t have long from the way his breaths were quickening.

“He’ll die, I’m begging you!“ San sobbed, more terrified than Hongjoong had ever seen him.

He was the cause of that panic.

“I’m sorry.”

He wouldn’t be there to take care of San anymore. This was all because he wanted to keep San safe from harm, but he’d been too slow yet again and now he was paying for it with his life and San would be alone after everything he’d done to bring Hongjoong in, abandoned by the only family he’d ever found.

San faced him again with a tear-streaked face and shook his head. “No, don’t say that, you’re going to be fine, you’ll see!” He was clutching the wounded wrist to the sopping material of his jeogori now in one hand and stroking Hongjoong’s wet face with the other, bloodstained hand. He could feel it smear over his cheek and the scent of it became overwhelming. “Don’t… don’t leave me now, alright? Promise?”

Exhaustion was washing over Hongjoong in the wake of white hot pain. He knew he would die soon, but he couldn’t bring himself to fight it.

His eye was growing increasingly vacant. He wanted to answer, but his lips didn’t move. The words worked their way up.

“I tried.”

He didn’t promise.

___

The air outside smelled like rain. It drifted in through an open window, distracting Hongjoong where he sat with his bags in the main room.

He frowned in worry as his parents handed him scroll after scroll to pack up. “Why are you giving me this?”

“In case something happens and we…” Mother stumbled over the words as she rolled the blueprints tightly and bundled them together. “…and we get separated. You can wait for us with the designs.”

Hongjoong protested weakly, “But, hyung—”

“Only has the key,” Father broke in, his voice extremely calm despite the way his hands fidgeted. It was the nervous sort of fidgeting, not the idle kind. “Hongjoong, your bag.”

Obediently, Hongjoong handed it over and tried to swallow down the uneasiness in his throat.

His parents were stuffing it full of blueprints of their designs, and although they didn’t explain why they were packing up their life’s work, the torches on the horizon were enough for Hongjoong to put two and two together.

He remembered the day, months before, when Beomjoong had put his own things into a sack and boarded a ferry that took him out of Joseon, never to return. Hongjoong had cried and clung to him the entire time on the wagon ride to the port, begging him not to go.

The entire thing had never been his choice but their parents’ decision, and Hongjoong resented them for it a little even now as they all prepared to follow him out of the country. To where, he had no idea.

He was fifteen now, and he understood why they couldn’t stay here any longer. He also understood why they had tried.

The Kims were a uniquely creative family of geniuses. The methods of harnessing steam power which they had devised were especially attractive to government ministries, and no matter how many times they said no, no matter how many times Hongjoong answered the door and politely informed the gentlemen that his parents weren’t interested in selling them, the officials returned and insisted.

It had led to their sending Beomjoong somewhere safer with the key to their most important design, an invention never built but often dreamed of, a key that could be used one day if such a machine was ever constructed.

But it could not be taken by the Ministry. In their hands, it would be a most fearsome weapon.

Knowing the key was safely elsewhere only took some of the load off their minds, with many designs still strewn about the house and an entire company of soldiers on their way.

“Quickly, son, your durumagi,” Mother fussed, fastening the coat as tightly as she could, worrying her lip between her teeth the entire time.

There was no reason for Hongjoong’s parents to hide their anxiety from him when he was old enough to know what was headed for their family.

The future was quite literally knocking on their door, and it would stop for no one.

“Head through the back and we’ll meet you near the wagons, alright?” Father instructed, helping him shoulder his bag properly before peeking through the paper blinds to see a large congregation of torch bearers outside.

“Please come soon,” Hongjoong whispered from the threshold, ashamed of his own fear when his parents turned to the door with such bravery. “You won’t leave me alone, right?”

They turned to look at him and smiled, shooing him out the back door.

Mother sounded so sure of herself.

“We’ll be right behind you.”

Hongjoong only made it down to the end of the road before seeing the smoke go up from his house.

His parents hadn’t followed as they said they would, and he knew the odds were greatly against them.

The waiting wagons were another ten minutes away, and he was still the only one on the road.

Mother and Father weren’t coming. They were stuck in a burning house, Hongjoong just knew it, and he knew they were throwing their lives away for no reason.

The remote possibility flashed across his mind as he stood there, frozen in the middle of the road, that this was all a trap. That the ministers wanted him to charge in and save them, so they could get the blueprints in their clutches again.

But Hongjoong wasn’t a child anymore. He could sneak in and save his parents without anyone knowing, he was sure of it.

And so he sprinted impulsively for home, one last time, thinking he could make a difference with his newfound bravery.

The smoke was billowing at a tremendous speed into the evening air, and the heat was so intense that Hongjoong could feel it from the other side of the stone wall, but he scaled it as easily as he had since he was a little boy and crawled into the house silently, holding his breath with practiced ease.

It was a nightmare.

Furniture was knocked over, trinkets and models were strewn across the floor, and the wooden frame of the house itself was on fire, consumed with a roaring blaze that climbed up curtains and licked away at the ceiling.

“Mother! Father!” Hongjoong cried out over the noise of the destruction. They were nowhere to be seen.

Hoping he could find them in another room and free them in time, he dragged himself along the floor, avoiding burning papers and dishes and making a beeline for the side rooms.

Tears pricked at his eyes from the thickness of the smoke, but he tried to remain calm while holding his breath, knowing if he inhaled it, he was as good as dead.

Suddenly, hands were wrapping around his midsection, lifting him upwards as if he weighed nothing and wrenching the bag from him.

“No!” He screamed, kicking blindly at his attacker, who dropped him face first to the ground and disappeared.

Hongjoong never even saw his face.

Feeling the flames encroaching, he realised his options were few. His parents may yet be somewhere inside, though the chances were growing slim by the second, and now he had to recover the designs from the man who had grabbed him, a man much bigger and stronger than he.

“Please…” he couldn’t keep a sniffle from escaping him as the terror of his situation descended on him.

For the first time in his life, he felt truly and utterly alone.

“Someone help!”

He knew there was no use in yelling. Any neighbours who cared to assist them would have done so by now, or else retreated to somewhere safer with their own valuable belongings.

Managing to stumble again to the back door, Hongjoong called out again, a yell that hardly sounded intelligible, and reached for the small patch of sky he could see through the haze of smoke.

At that moment, the doorframe collapsed, sparks went flying, and all Hongjoong knew was a searing pain in his eye before he was writhing on the ground.

His hands were pressed to his face, blood dripped through his fingers, and he was trapped now with no way out.

Elsewhere in the burning house, his parents breathed their last.

They had died so Hongjoong could escape. And he had brought their designs right into the lap of the Ministry.

Guilt that stung more than the pain of his wound burned through him and Hongjoong surrendered, a sobbing mess on the floor, to whatever fate had next for him.

He did not expect to wake.

___

Taglist: @p4rk-junhee

A/N: Things are ramping up now! Hopefully you’ll stick around as our characters continue to be slowly introduced :D let me know if you'd like to be on the taglist and what you thought of this chapter in the comments! And stay tuned for more updates on various works because it's starting to look like I've finally killed my writer's block!!!

← Previous | Masterlist | Next →

#ateez#ateez fanfiction#ateez fanfic#tokki writes#ateez au#ateez angst#ateez fic#ateez hongjoong#ateez seonghwa#ateez yunho#ateez yeosang#ateez san#ateez mingi#ateez wooyoung#ateez jongho#mechanosis#joseon era#steampunk au

8 notes

·

View notes

Text

SEMANTIC TREE AND AI TECHNOLOGIES

Semantic Tree learning and AI technologies can be combined to solve problems by leveraging the power of natural language processing and machine learning.

Semantic trees are a knowledge representation technique that organizes information in a hierarchical, tree-like structure.

Each node in the tree represents a concept or entity, and the connections between nodes represent the relationships between those concepts.

This structure allows for the representation of complex, interconnected knowledge in a way that can be easily navigated and reasoned about.

CONCEPTS

Semantic Tree: A structured representation where nodes correspond to concepts and edges denote relationships (e.g., hyponyms, hyponyms, synonyms).

Meaning: Understanding the context, nuances, and associations related to words or concepts.

Natural Language Understanding (NLU): AI techniques for comprehending and interpreting human language.

First Principles: Fundamental building blocks or core concepts in a domain.

AI (Artificial Intelligence): AI refers to the development of computer systems that can perform tasks that typically require human intelligence. AI technologies include machine learning, natural language processing, computer vision, and more. These technologies enable computers to understand reason, learn, and make decisions.

Natural Language Processing (NLP): NLP is a branch of AI that focuses on the interaction between computers and human language. It involves the analysis and understanding of natural language text or speech by computers. NLP techniques are used to process, interpret, and generate human languages.

Machine Learning (ML): Machine Learning is a subset of AI that enables computers to learn and improve from experience without being explicitly programmed. ML algorithms can analyze data, identify patterns, and make predictions or decisions based on the learned patterns.

Deep Learning: A subset of machine learning that uses neural networks with multiple layers to learn complex patterns.

EXAMPLES OF APPLYING SEMANTIC TREE LEARNING WITH AI.

1. Text Classification: Semantic Tree learning can be combined with AI to solve text classification problems. By training a machine learning model on labeled data, the model can learn to classify text into different categories or labels. For example, a customer support system can use semantic tree learning to automatically categorize customer queries into different topics, such as billing, technical issues, or product inquiries.

2. Sentiment Analysis: Semantic Tree learning can be used with AI to perform sentiment analysis on text data. Sentiment analysis aims to determine the sentiment or emotion expressed in a piece of text, such as positive, negative, or neutral. By analyzing the semantic structure of the text using Semantic Tree learning techniques, machine learning models can classify the sentiment of customer reviews, social media posts, or feedback.

3. Question Answering: Semantic Tree learning combined with AI can be used for question answering systems. By understanding the semantic structure of questions and the context of the information being asked, machine learning models can provide accurate and relevant answers. For example, a Chabot can use Semantic Tree learning to understand user queries and provide appropriate responses based on the analyzed semantic structure.

4. Information Extraction: Semantic Tree learning can be applied with AI to extract structured information from unstructured text data. By analyzing the semantic relationships between entities and concepts in the text, machine learning models can identify and extract specific information. For example, an AI system can extract key information like names, dates, locations, or events from news articles or research papers.

Python Snippet Codes for Semantic Tree Learning with AI

Here are four small Python code snippets that demonstrate how to apply Semantic Tree learning with AI using popular libraries:

1. Text Classification with scikit-learn:

```python

from sklearn.feature_extraction.text import TfidfVectorizer

from sklearn.linear_model import LogisticRegression

# Training data

texts = ['This is a positive review', 'This is a negative review', 'This is a neutral review']

labels = ['positive', 'negative', 'neutral']

# Vectorize the text data

vectorizer = TfidfVectorizer()

X = vectorizer.fit_transform(texts)

# Train a logistic regression classifier

classifier = LogisticRegression()

classifier.fit(X, labels)

# Predict the label for a new text

new_text = 'This is a positive sentiment'

new_text_vectorized = vectorizer.transform([new_text])

predicted_label = classifier.predict(new_text_vectorized)

print(predicted_label)

```

2. Sentiment Analysis with TextBlob:

```python

from textblob import TextBlob

# Analyze sentiment of a text

text = 'This is a positive sentence'

blob = TextBlob(text)

sentiment = blob.sentiment.polarity

# Classify sentiment based on polarity

if sentiment > 0:

sentiment_label = 'positive'

elif sentiment < 0:

sentiment_label = 'negative'

else:

sentiment_label = 'neutral'

print(sentiment_label)

```

3. Question Answering with Transformers:

```python

from transformers import pipeline

# Load the question answering model

qa_model = pipeline('question-answering')

# Provide context and ask a question

context = 'The Semantic Web is an extension of the World Wide Web.'

question = 'What is the Semantic Web?'

# Get the answer

answer = qa_model(question=question, context=context)

print(answer['answer'])

```

4. Information Extraction with spaCy:

```python

import spacy

# Load the English language model

nlp = spacy.load('en_core_web_sm')

# Process text and extract named entities

text = 'Apple Inc. is planning to open a new store in New York City.'

doc = nlp(text)

# Extract named entities

entities = [(ent.text, ent.label_) for ent in doc.ents]

print(entities)

```

APPLICATIONS OF SEMANTIC TREE LEARNING WITH AI

Semantic Tree learning combined with AI can be used in various domains and industries to solve problems. Here are some examples of where it can be applied:

1. Customer Support: Semantic Tree learning can be used to automatically categorize and route customer queries to the appropriate support teams, improving response times and customer satisfaction.

2. Social Media Analysis: Semantic Tree learning with AI can be applied to analyze social media posts, comments, and reviews to understand public sentiment, identify trends, and monitor brand reputation.

3. Information Retrieval: Semantic Tree learning can enhance search engines by understanding the meaning and context of user queries, providing more accurate and relevant search results.

4. Content Recommendation: By analyzing the semantic structure of user preferences and content metadata, Semantic Tree learning with AI can be used to personalize content recommendations in platforms like streaming services, news aggregators, or e-commerce websites.

Semantic Tree learning combined with AI technologies enables the understanding and analysis of text data, leading to improved problem-solving capabilities in various domains.

COMBINING SEMANTIC TREE AND AI FOR PROBLEM SOLVING

1. Semantic Reasoning: By integrating semantic trees with AI, systems can engage in more sophisticated reasoning and decision-making. The semantic tree provides a structured representation of knowledge, while AI techniques like natural language processing and knowledge representation can be used to navigate and reason about the information in the tree.

2. Explainable AI: Semantic trees can make AI systems more interpretable and explainable. The hierarchical structure of the tree can be used to trace the reasoning process and understand how the system arrived at a particular conclusion, which is important for building trust in AI-powered applications.

3. Knowledge Extraction and Representation: AI techniques like machine learning can be used to automatically construct semantic trees from unstructured data, such as text or images. This allows for the efficient extraction and representation of knowledge, which can then be used to power various problem-solving applications.

4. Hybrid Approaches: Combining semantic trees and AI can lead to hybrid approaches that leverage the strengths of both. For example, a system could use a semantic tree to represent domain knowledge and then apply AI techniques like reinforcement learning to optimize decision-making within that knowledge structure.

EXAMPLES OF APPLYING SEMANTIC TREE AND AI FOR PROBLEM SOLVING

1. Medical Diagnosis: A semantic tree could represent the relationships between symptoms, diseases, and treatments. AI techniques like natural language processing and machine learning could be used to analyze patient data, navigate the semantic tree, and provide personalized diagnosis and treatment recommendations.

2. Robotics and Autonomous Systems: Semantic trees could be used to represent the knowledge and decision-making processes of autonomous systems, such as self-driving cars or drones. AI techniques like computer vision and reinforcement learning could be used to navigate the semantic tree and make real-time decisions in dynamic environments.

3. Financial Analysis: Semantic trees could be used to model complex financial relationships and market dynamics. AI techniques like predictive analytics and natural language processing could be applied to the semantic tree to identify patterns, make forecasts, and support investment decisions.

4. Personalized Recommendation Systems: Semantic trees could be used to represent user preferences, interests, and behaviors. AI techniques like collaborative filtering and content-based recommendation could be used to navigate the semantic tree and provide personalized recommendations for products, content, or services.

PYTHON CODE SNIPPETS

1. Semantic Tree Construction using NetworkX:

```python

import networkx as nx

import matplotlib.pyplot as plt

# Create a semantic tree

G = nx.DiGraph()

G.add_node("root", label="Root")

G.add_node("concept1", label="Concept 1")

G.add_node("concept2", label="Concept 2")

G.add_node("concept3", label="Concept 3")

G.add_edge("root", "concept1")

G.add_edge("root", "concept2")

G.add_edge("concept2", "concept3")

# Visualize the semantic tree

pos = nx.spring_layout(G)

nx.draw(G, pos, with_labels=True)

plt.show()

```

2. Semantic Reasoning using PyKEEN:

```python

from pykeen.models import TransE

from pykeen.triples import TriplesFactory

# Load a knowledge graph dataset

tf = TriplesFactory.from_path("./dataset/")

# Train a TransE model on the knowledge graph

model = TransE(triples_factory=tf)

model.fit(num_epochs=100)

# Perform semantic reasoning

head = "concept1"

relation = "isRelatedTo"

tail = "concept3"

score = model.score_hrt(head, relation, tail)

print(f"The score for the triple ({head}, {relation}, {tail}) is: {score}")

```

3. Knowledge Extraction using spaCy:

```python

import spacy

# Load the spaCy model

nlp = spacy.load("en_core_web_sm")

# Extract entities and relations from text

text = "The quick brown fox jumps over the lazy dog."

doc = nlp(text)

# Visualize the extracted knowledge

from spacy import displacy

displacy.render(doc, style="ent")

```

4. Hybrid Approach using Ray:

```python

import ray

from ray.rllib.agents.ppo import PPOTrainer

from ray.rllib.env.multi_agent_env import MultiAgentEnv

from ray.rllib.models.tf.tf_modelv2 import TFModelV2

# Define a custom model that integrates a semantic tree

class SemanticTreeModel(TFModelV2):

def __init__(self, obs_space, action_space, num_outputs, model_config, name):

super().__init__(obs_space, action_space, num_outputs, model_config, name)

# Implement the integration of the semantic tree with the neural network

# Define a multi-agent environment that uses the semantic tree model

class SemanticTreeEnv(MultiAgentEnv):

def __init__(self):

self.semantic_tree = # Initialize the semantic tree

self.agents = # Define the agents

def step(self, actions):

# Implement the environment dynamics using the semantic tree

# Train the hybrid model using Ray

ray.init()

config = {

"env": SemanticTreeEnv,

"model": {

"custom_model": SemanticTreeModel,

},

}

trainer = PPOTrainer(config=config)

trainer.train()

```

APPLICATIONS

The combination of semantic trees and AI can be applied to a wide range of problem domains, including:

- Healthcare: Improving medical diagnosis, treatment planning, and drug discovery.

- Finance: Enhancing investment strategies, risk management, and fraud detection.

- Robotics and Autonomous Systems: Enabling more intelligent and adaptable decision-making in complex environments.

- Education: Personalizing learning experiences and providing intelligent tutoring systems.

- Smart Cities: Optimizing urban planning, transportation, and resource management.

- Environmental Conservation: Modeling and predicting environmental changes, and supporting sustainable decision-making.

- Chatbots and Virtual Assistants:

Use semantic trees to understand user queries and provide context-aware responses.

Apply NLU models to extract meaning from user input.

- Information Retrieval:

Build semantic search engines that understand user intent beyond keyword matching.

Combine semantic trees with vector embeddings (e.g., BERT) for better search results.

- Medical Diagnosis:

Create semantic trees for medical conditions, symptoms, and treatments.

Use AI to match patient symptoms to relevant diagnoses.

- Automated Content Generation:

Construct semantic trees for topics (e.g., climate change, finance).

Generate articles, summaries, or reports based on semantic understanding.

RDIDINI PROMPT ENGINEER

#semantic tree#ai solutions#ai-driven#ai trends#ai system#ai model#ai prompt#ml#ai predictions#llm#dl#nlp

3 notes

·

View notes

Text

Working on Sophias Story again :D

-> A little later, Sophia reached maintenance shaft [xy], where the main security system of the SD of the Abyss Chrusher was located. The light activated by a motion sensor flared up in cold white with a delay of a few seconds. Neon Xilkor tubes of the NX-6 series had this somewhat unpleasant habit, which the manufacturer Asterisk never rectified. Despite this, Hallinger-FTL continued to install them in all maintenance rooms of their ship series to this day. The Davar class in particular suffered from this fact, as it had a higher number of such areas due to its modular design. As a result, Sophia had only been able to recognise the large control cabinets and component racks by the myriad of flashing LEDs when she arrived. This sea of red, orange and green diodes, which greeted her auspiciously from the steel racks, secretly watched over the entire crew and ensured that the safety units of the individual SERAHs were working.

Now that the white light flooded the room, she saw it in its entirety, and with it the technology inside. In contrast to the blinking confusion of the Sevix control racks on the right side of the room, the Servagul control cabinets on her left, unusual for a Davar-class ship, emitted a soft green glow. The reason for this was that Servagul built light panels into the doors of their products, which no self-respecting shipbuilder needed. Such nice lighting did nothing but waste power unnecessarily. Sure, ships like the Abyss Chrusher might not lack power, but that was no reason to be so wasteful.

Shrugging her shoulders, the engineer lifted her tool and the testing device before taking them to the control cabinet labelled SUR-2, where she set them down. She unlocked the door with her CAM and the handle whirred out, allowing her to open the cabinet. Sophia sighed, pulled open the cupboard door and, coloured by the light from the front panel, saw another flood of flashing or glowing diodes emanating from the security register cards. It was a sight that filled the engineer with joy, because she had hardly been able to wait to get back into the bowels of the Abyss Chrusher, but the work that was to follow was rather dull. So she plugged her headphones into her CAM, put them in her ears and switched on an album by a band Liv had shown her a few days ago. A harsh guitar riff accompanied by the vocals of a woman singing in the language of the Marlan system rang out.

She then began checking the security tabs, which initially consisted of informing the SD-SERAH of her work via the control panel in the top frame of the device. In fact, Sophia was only slightly keen on an emergency lockout of the SD, even if she could override it with her system authorisations. Basically, you had to give Servagul and Sevix credit for the cleverness of their products. After all, the automatic security system, which according to Ela - unfortunately there were no plans on this subject - summarised one subsystem of the drive per cabinet in order to pass them on to SERAH in a bundle.

You could imagine the tabs and their subsystems as the nervous system of a body, which transmitted every pain of the machines to the consciousness or to an AI. SERAH then reported the information to the Abyss Chrusher's SAM, the ship's main AI, which ensured that appropriate action was taken. What the SERAH was to the SD, the SAM was to the entire ship.

Sophia pulled a small screwdriver from the side pocket on her left arm. She used it to loosen the two neck screws on the top and bottom of the front panel of each of the seven assemblies. She was then able to pull them out by the handle to insert them into the test device. This established a serial, wired connection with the fuse register in order to then interrogate the main function of the unit on the two circuit boards of the modules. For this purpose, the test device simulated a fault by sending a specific signal sequence via the bus interface. The module processed this within a few femtoseconds and signalled an alarm back to the test device. At least that's how it worked when everything was OK. The process only took a few blinks of the eye until the technical measurement results - such as resistance, time and induction values - appeared on the display of the test device. Confirmation of the success or failure of the analysis could then also be obtained.<-

The story of the empty sky - 1 Dreams of electronic tears Chapter 10, A fairy tale of normality

#writing#booklr#books#books and reading#books and literature#writerscorner#author#books & libraries#writers on tumblr#science fiction#science fantasy#spaceship

2 notes

·

View notes

Text

What are the latest warehouse automation technologies?

Gone are the days of manual labour and static, inefficient operations. Today, we stand at the forefront of a revolution driven by the latest warehouse automation technologies. These innovations reshape how businesses handle inventory, fulfil orders, and optimize supply chains.

From autonomous robots and artificial intelligence to the Internet of Things (IoT) and advanced data analytics, we'll explore how these technologies enhance efficiency, reduce costs, and ensure seamless operations in modern warehouses.

1-Robotic Process Automation (RPA): RPA involves using software robots to automate repetitive tasks like data entry, order processing, and inventory tracking. The robots interact with various systems and applications to streamline workflows.

2-Autonomous Mobile Robots (AMRs): Robotic vehicles called AMRs navigate and operate in warehouses without fixed infrastructure, such as conveyor belts or tracks. They perform tasks like picking, packing, and transporting goods.

3-Automated Guided Vehicles (AGVs): AGVs are similar to AMRs but typically follow fixed paths or routes guided by physical markers or magnetic tape. They are commonly used for material transport in warehouses and distribution centres.

4-Goods-to-Person Systems: This approach involves bringing the items to the workers rather than having workers travel throughout the warehouse to pick items. Automated systems retrieve and deliver goods to a workstation, reducing walking time and improving efficiency.

5-Automated Storage and Retrieval Systems (AS/RS): AS/RS systems use robotics to store and retrieve items from racks or shelves automatically. These systems can significantly increase storage density and optimize space utilization.

6-Collaborative Robots (Cobots): Cobots are designed to work alongside human workers. They can assist with tasks like picking, packing and sorting, enhancing efficiency and safety.

7-Warehouse Management Systems (WMS): While not a physical automation technology, modern WMS software uses advanced algorithms and AI to optimize inventory management, order fulfilment, and warehouse processes.

8-Vision Systems and Machine Learning: Computer vision technology combined with machine learning can be utilized for tasks such as object recognition, inventory movement tracking, and quality control.

9-IoT and Sensor Networks: Internet of Things (IoT) devices and sensors collect real-time data on inventory levels, environmental conditions, equipment health, and more, enabling better decision-making and predictive maintenance.